Applications

● Cell disruption: E. coli, yeast, algae, etc.

● Emulsion preparation

● Liposome

● Medicine

Performance

● Comply with GMP and FDA hygiene standards.

● High crushing rate, one-time crushing rate can exceed 95%.

● High hygienic level, and can meet the requirements of food and drug production.

Technical Features

● Automated operation

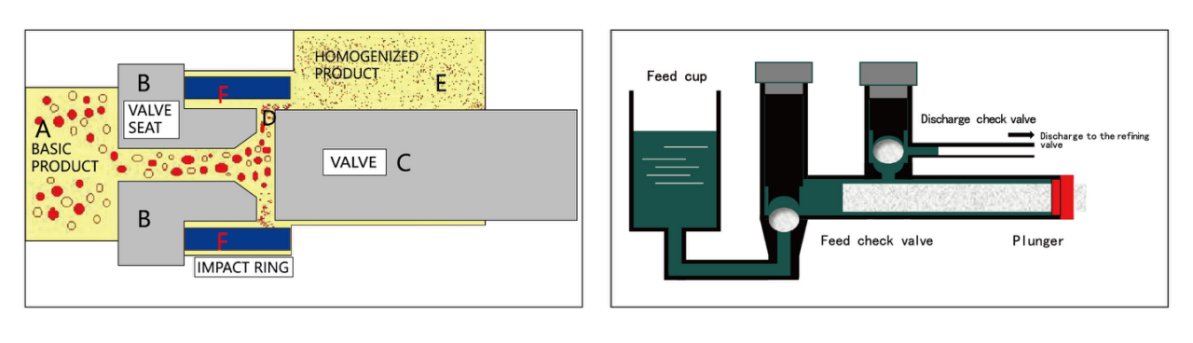

—Automatic sample injection, continuous operation, no venting required.

● Equipment material

—Adopt 316L stainless steel with high hygienic level, high-temperature resistant, wear-resistant and anti- corrosion.

—Plunger rod is made of special ceramics, which are durable and have a long service life.

—Homogenising valve materials are available in diamond and stellite alloys, configured to suit the customer's application.

● Temperature controllable

—The inlet and outlet of the cooling joint are connected to the constant temperature bath, which effectively controls the temperature rise of the homogeneous material.

● Safety control

—Automatically cut off the controller circuit.

● Modular structure, easy to operate and maintain.

● Triple overvoltage safety protection system:

—Equipped with BOS inverter for overload start protection.

—Equipment adopts Italian GEFRAN, when pressure exceeds 10% of sensor range value, the sensor will sends the signal of the unit, and then the machine stops for self-protection.

—Equipped with safety valve for pressure relief system.

Working principle

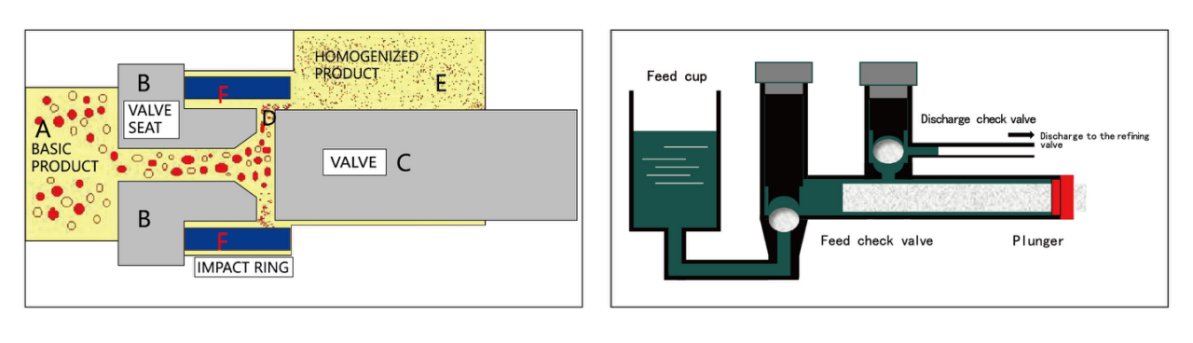

Under the reciprocating motion of the plunger, the material is transported to a valve group with adjustable size, and is subjected to extremely strong compression. When passing through the current limiting slit, the material hits the valve at a very fast speed, resulting in cavitation effect, impact effect and shear effect, so that the aggregated material is evenly dispersed.