1. Introduction

The core component of the microfluidization homogenizer is a homogenizer module that can withstand extremely high pressures, up to 30,000 psi. The structure of its core components can be divided into Y cavity and Z cavity according to its design, as well as nozzles with different pore sizes, which are the core positions of materials subjected to shearing force, collision, hole effect and other physical effects under high pressure, which can achieve material dispersion or particle size control and the improvement of joint width and small.

2. Component composition

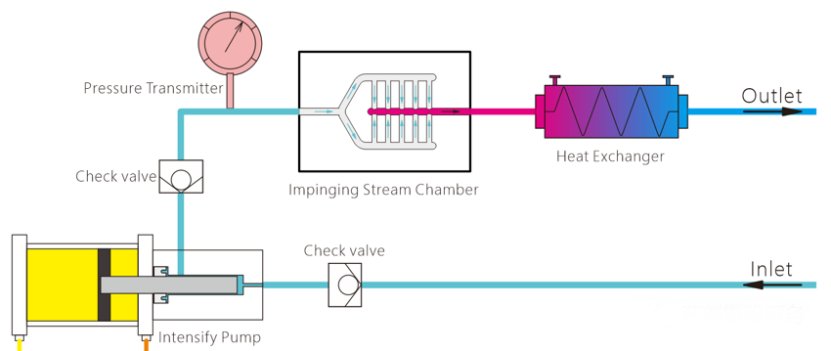

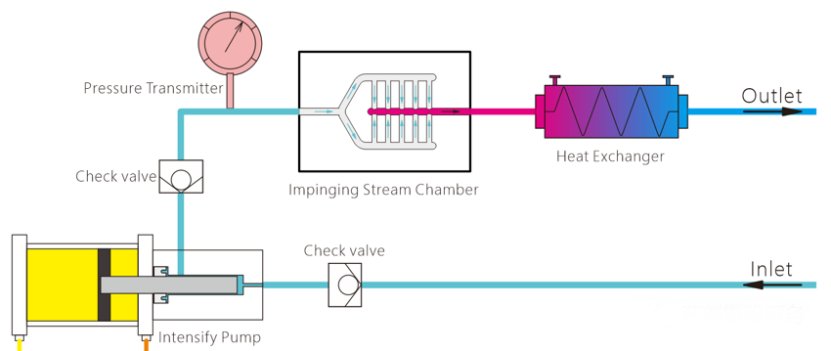

The microfluidization homogenizer is mainly composed of feed cup, check valve, hydraulic pump, high-pressure pressure gauge, Y /Z type homogenizer chamber, heat exchanger and discharge port. The microfluidization homogeneous cavity plays a key role in reducing the particle size of the material. Its material is suitable for different materials according to different materials, diamond, ceramics and other materials suitable for high hardness, wear resistance and corrosion resistance. The booster plunger in the hydraulic pump adopts zirconia ceramic, which is resistant to wear, corrosion and is not easy to generate static electricity.

3. Working principle

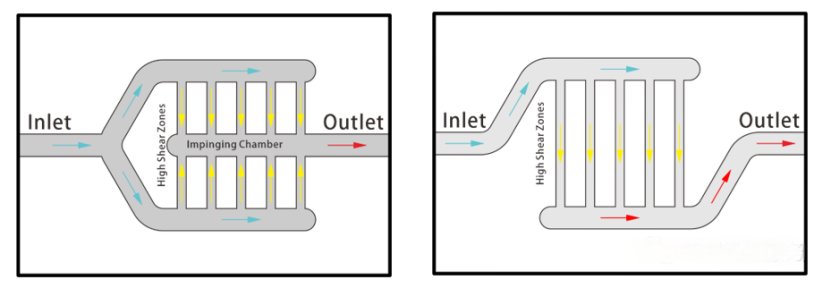

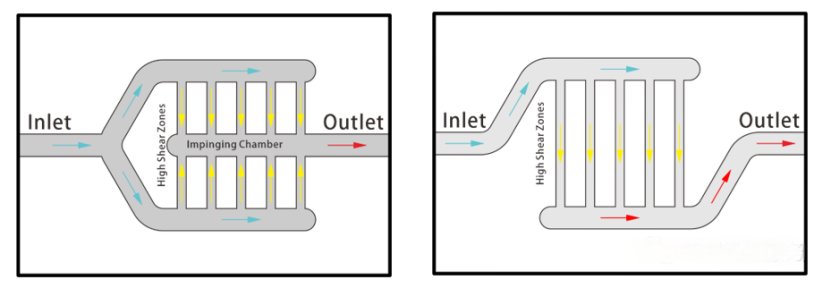

The material passes through the check valve, pressurizes in the high pressure chamber pump, and passes through the microfluidic homogeneous Y cavity module. In the micro-pore channel (75μm or 100um) in the interactive chamber, the fluid is dispersed into two streams for strong high-speed impact and high-speed shear. Through the micropore channel (200μm) of the microfluidic homogeneous Z cavity module, most of its energy is transformed instantaneously during the jet impact process. Accompanied by huge pressure drop, the whole process includes high-speed impact, high shear force, cavity action, high-frequency vibration and other comprehensive effects to achieve the purpose of crushing, so that the droplet or crystal particle size is reduced. The fixed and constant geometric structure of the microfluidic diamond interactive cavity ensures that under the condition of the same number of pretreatment and use pressure, each milliliter of material is subjected to the same physical force through the diamond interactive cavity, thus ensuring excellent result repeatability and stability. The side-by-side replication of the single-channel micro-jet diamond interactive cavity to the multi-channel microfluidic diamond interactive cavity is achieved. To ensure the treatment effect while processing flow doubling, to ensure that the experimental research and development of the process is linearly scaled up to industrial production.

4. Application of microfluidization homogenizer in nanomedicine

Microfluidic homogenization technology is a new preparation technology of nanomaterials. The main influencing factors are the treatment pressure, the number of cycles, the nature of the drug and the choice of surfactant or stabilizer. It can be applied to the preparation of nano-drugs such as nano-emulsion, LNP nano-liposome and nano-suspension.

5. Nanoemulsion

Nanoemulsions are non-equilibrium systems, the formation of which requires external energy, usually from mechanical equipment or chemical agents, and the particle size is usually 20-200nm. The type and dosage of surfactants are the key to the stability of nanoemulsion. Common surfactants include Poloxam, Tween 80, lecithin, etc.

The microfluidization homogenizer provides the required energy in the shortest time and obtains the smallest particle size uniform emulsion. It has been shown that the average particle size of the nano emulsion treated by the microfluidization homogenizer for vitamin E cream is 65nm, while the average particle size of the micron emulsion obtained by the traditional method is 2788nm.

6. Lipidosome

Liposomes are spherical lipid biofilm microspheres with single or multi-layer double lipid membrane structure. There are many ways to prepare liposomes, but most of them are not suitable for large-scale and continuous production. The microfluidization homogenizer has good adaptability and good effect in industrial application. The average particle size of realel nano-liposomes prepared by thin film dispersion-microfluidization homogenizer mechanism is 102.3nm, the drug encapsulation rate is 82.28%, and the dispersion stability is good.

7. Nano suspension

Nano suspension is a kind of liquid preparation which is formed by dispersing insoluble solid pure drug in the dispersing medium with a small amount of surfactant as stabilizer. The drugs to prepare nanoemulsion should have a large fat solubility, and the nano-suspension is suitable for most drugs. The gastric acid secretion inhibitor omeprazole nanosuspension was prepared by circulating at 1500bar for 40 times with a high-pressure microfluidization homogenizer, and still had good stability when stored at 0℃ for one month.